LEGO’s waste line

In 2018 LEGO announced they started sourcing raw materials for their plastic parts from plant origins instead of petroleum. In September of 2020, LEGO announced that they would be replacing the plastic bags used to package bricks with paper bags. While we have seen the plastic parts become a reality, ten months after the announcement, we have yet to see the paper bags here on the poor side of the street. So, while we are all waiting for FSC-approved paper bags to arrive, and sparing you a tirade on how I think the FSC is a self-important body interjecting itself into the supply chain for their own financial benefit, let’s take a moment to look at one other place where LEGO could improve their environmental consciousness.

On a recent trip to the consumer wonderland known as the mall for other reasons, my son decided we needed to visit the LEGO store. I would end up spending part of his inheritance but not the wife’s egg money there. Being that there was a set I wanted, but not in the store, resulted in a subsequent online purchase…the point here being I acquired several different LEGO products requiring one trip by me and another by the delivery person. Had the product been in the store we could have avoided a trip by the delivery person. Here I admit my environmental failing in that I could have foregone that which wasn’t in the store. So while I’m a victim of my own selfish desire, at least I had enough wits not to spend the egg money.

That should suffice for preface. Being observational as I am, and generally having too much time to think about stuff between the time I waited for BrickLink pages to load during that BDP launch and the eventual opening of the sets ordered online, I noticed something in regard to LEGO packaging.

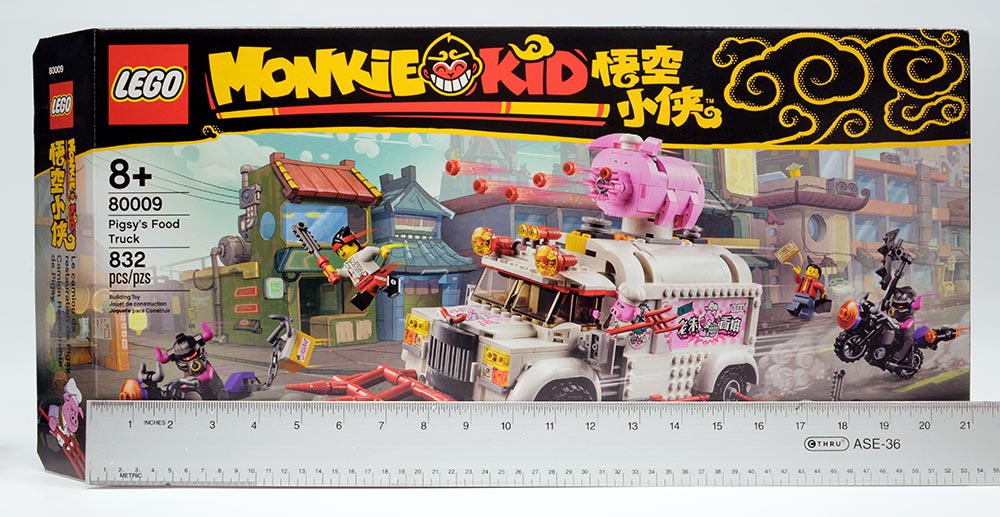

80009 Pigsy’s Food Truck

This set comes in a box approximately 21 x 11 x 3 inches / 53 x 28 x 7 centimeters. Simply setting the box on end, not setting the box on end and doing anything to settle the contents, just setting the box on end to slit the tape seals to open the box…I notice the box is not at all full. Yes, I noticed this all by myself without assistance or pharmacological enhancement.

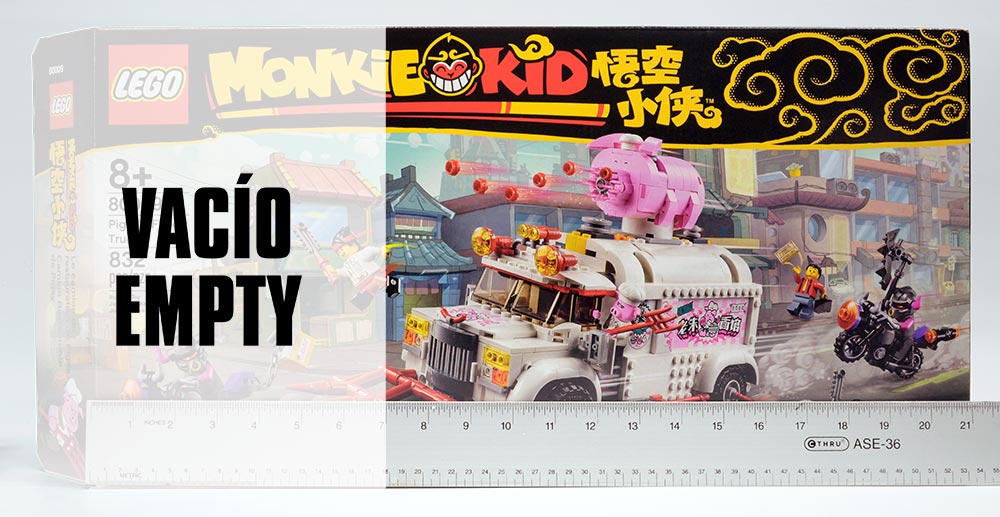

Slipping a ruler into the box, I find about 8 inches / 20 centimeters of empty space. This is about one third of the box.

Let’s give LEGO the benefit of the doubt for needing some “extra” space within a box for production reasons. But a third? Here is a visual representation of a third of this box being empty.

40373 Fairground Minifigure Pack, 40345 City Minifigure Pack, 40472 Monkie Kid Minifigure Pack

The packaging for these products is wasteful, to say the least. The plastic blister tray alone has enough capacity to hold all the parts, so why add all the cardboard? The plastic blister is one-use plastic, and if we are lucky 30% of that might find its way back into the manufacturing stream. The cardboard alone measures 32 x 27 centimeters, and if reconfigured into a box would be more than ample to contain the product. Rough measurements would indicate that a 24 x 18 centimeter sheet configured into a simple 6 x 6 x 6 centimeter (216cm3) box would be sufficient to hold the product. For comparison purposes, the parts in the Fairground Minifigure Pack will all fit into a 9 x 9 x 2 centimeter (168cm3) VIDIYO Bandmates box, albiet without the typical plastic baggie around it.

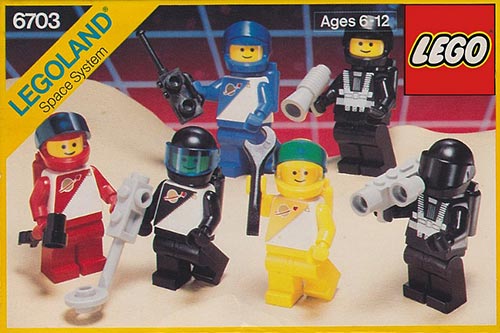

Tell me, dear reader, what is the upside to putting product in a package that requires about 4 times the shelf space, 30% more cardboard than is necessary, and a completely wasteful plastic shell? No. Seriously. Tell me. I’m still waiting for BrickLink pages to load. I have time. LEGO used to sell six minifigures in a simple rectangular box back in the late 1980’s. For example, 6703 Space Minifigures came in a box measuring approximately 12 x 7 x 4 centimeters which would translate into a sheet about 28 x 26 centimeters. 6102 and 6103 Castle Minifigures were in similarly small (not identical) sized boxes as were other Minifigure packs of the era.

© LEGO, Courtesy Brickset

© LEGO, Courtesy Brickset

Now, I will grant you that there will be some technical consideration of sheet size, press size, die cuts, waste, and so on that goes into the production considerations for any packaging. It may or may not be the case where the cardboard for the new Minifigure packs, those with the plastic blister, are actually being cut from the same size press sheet as the older boxes. For argument’s sake, let’s say that they are. Okay. So why include the plastic blister in the new packaging at all? Marketing may say that it is so the consumer can see the actual product. Well, okay, that’s pretty damned lame for an argument. One, the big packages don’t have windows so you can see what’s inside. Two, it is pretty difficult to see everything when it is randomly arranged in a crinkled glare reflecting plastic bag inside an odd-shaped molded glare reflecting plastic blister. If you want to know what is in the package, it is clearly (and please note I clearly use the word clearly on purpose here) far easier to refer to the illustration to the side of the blister than to try to decipher the mixed up content within the blister. And we can argue marketing reasons pro and con all day, but in the end, the new packaging is using about twice the material of the old packaging. The old packaging was completely biodegradable and the new isn’t.

So, can somebody mansplain to me the logic with this excess packaging? In regards to the Pigsy box, good gravy Marie! One would think that the box could be at least one-third smaller. The Minifigure Packs, yikes, the production complexities of putting pieces into a bag, then into a shell, then into a cardboard sleeve, then folding the sleeve over and gluing and taping it…that has to be substantially less cost-effective than just putting the baggie into a box. I mean, the tooling required to assemble that package has to be a thing, right?

While Pigsy and the Minifigure Packs may be extreme examples of excess space-wasting, it should be obvious that reducing package size would allow additional packages to fit in a case box, meaning more product on a pallet, put onto a truck to be shipped wherever stuff is shipped…and theoretically as a result fewer truck trips needed to get stuff where it’s going. Fewer truck trips is less gas consumed and less pollution produced. Corporate savings should be realized along with an environmental benefit.

Reducing the packaging is not difficult and does not require a marketing blitz, although if implemented may warrant one. So, how about it, LEGO? Can you really go all-in on the environmental responsibility? At the very least, get rid of the single-use plastic. Please? It’s just a little bit hard to swallow any story about creating plastic from plants being environmentally responsible if you then turn around and make needless single-use blister packs from it.

33476