LEGO Covid-19 visors - a few questions answered

About 6 weeks ago we posted about LEGO transforming some of its production capacity to make protective visors for medical personnel.

With the help of the LEGO Ambassador Network AFOL Engagement Team (AFOLET), we had the opportunity to ask the team behind these visors a few questions in writing. Brickset, BrickFinder, New Elementary, HispaBrick Magazine and the Ramblingbrick compiled a list of questions and today we publish the answers we received:

Q - Where did the idea for this come from, an employee or senior management… or a government request?

A - In March, Mikkel Schildknecht Hoé, a Senior Equipment Manager in our Engineering department, heard that there was a desperate need for safety equipment for COVID-19 in Denmark. He approached the rest of his team with his idea for a visor and they started to trial production ideas. The design and quality was approved by local health authorities. Approximately 100 LEGO employees have been involved in this project in Denmark and Hungary, from developing the design and new moulds, to working with our supplies to make the visors a reality in just a couple of weeks.

Q - It sounds bizarre for a toy company to be making PPE but we forget TLG is ultimately a plastics moulding company with 70 years of experience! Was it much of a challenge to produce these?

A - Usually the process of making new moulds takes about six months but in this case we were able to work with our suppliers to make the visors a reality in just a couple of weeks. We were able to produce new moulds and convert a number of existing moulding machines in Billund and Nyíregyháza (Hungary).

Q - What was your biggest challenge?

We thought that one of the biggest challenges would be time. Usually it can take up to six months for new moulds to be made and we wanted to meet the demand quickly. But time actually turned out to be a great motivator. More than 100 members of staff offered to help with the project so we could get visors into production quickly, some working seven days a week and over the Easter holidays to fast-track production. Everyone wanted to do their bit to help our frontline health workers.

Q - What LEGO elements are the masks closest to, in terms of the production methods used?

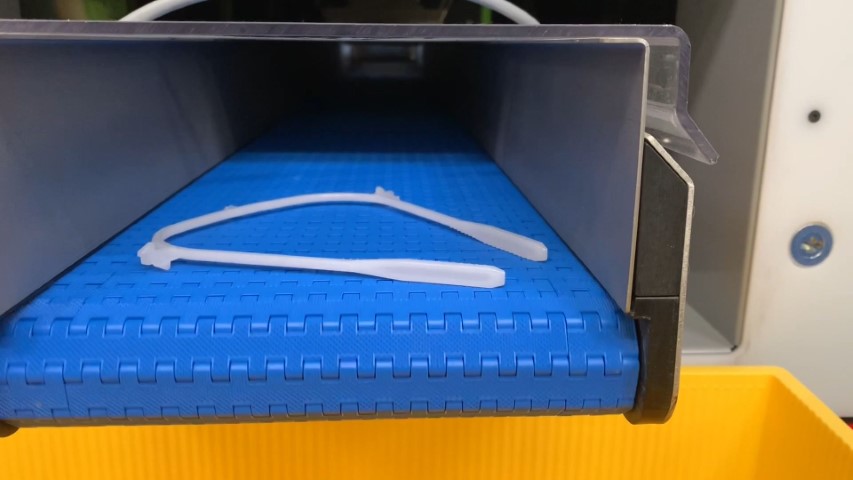

A - The visors were developed with the Danish Health Authorities. For this reason the production method is unique to the visors and not comparable to the production of other LEGO elements. The visor elements have been given unique design IDs to help with production processes, but they don't have "LEGO" stamped on them.

Q - The quality of plastic that TLG use for elements is extremely high - other companies even purchase the waste plastic TLG produce because its quality is still so good for their purposes! - did you use the same super high quality plastic for the masks or was that an unnecessary expense for what is essentially a disposable item?

A - We used the same materials as we do in our other elements. We also made sure that the visors produced meet the same stringent quality standards as all other LEGO elements.

Q - Were the masks used only in Denmark or also in other countries?

A - Our priority was to first help the Danish Health Service as we could ship visors quickly. We have also begun making the visors in Nyíregyháza and recently donated 65,000 to doctors working in the region. We have also donated visors to health workers in Mexico. Our focus is on providing visors as a donation for frontline healthcare workers (e.g. hospital staff, staff in nurseries, care homes, dentists) in our local communities in Denmark, Hungary, Czech Republic and Mexico.

One last question that came up was regarding the availability of these visors for collectors. We would all have loved to be able to personally touch and inspect this LEGO product, but it is only logical that every single mask should go to the people who really need it in order to safely take care of those who need their services.

Finally, we were given a short video presentation that shows the production process of these visors. (you have already seen a few screenshots in the article):

9454